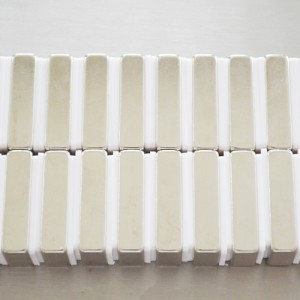

SmCo Magnet

| Sintered SmCoMagnetThepa ea 'Mele | |||||||||

| Lintho tse bonahalang | Kereiti | Remanence | Moruti Temp.- Coeff. Ea Br | Matla a Qobellang | Matla a Koetliso a ka hare | Moruti Temp.-Coeff. Ea Hcj | Max. Sehlahisoa sa Matla | Max. Mocheso oa ho sebetsa | Botenya |

| Br (KGs) | Hcb (WENA) | Hcj (WENA) | (BH) max. (MGOe) | g/cm³ | |||||

| SmCo5 | XG16 | 8.1-8.5 | -0.050 | 7.8-8.3 | 15-23 | -0.30 | 14-16 | 250 ℃ | 8.3 |

| XG18 | 8.5-9.0 | -0.050 | 8.3-8.8 | 15-23 | -0.30 | 16-18 | 250 ℃ | 8.3 | |

| XG20 | 9.0-9.4 | -0.050 | 8.5-9.1 | 15-23 | -0.30 | 19-21 | 250 ℃ | 8.3 | |

| XG22 | 9.2-9.6 | -0.050 | 8.9-9.4 | 15-23 | -0.30 | 20-22 | 250 ℃ | 8.3 | |

| XG24 | 9.6-10.0 | -0.050 | 9.2-9.7 | 15-23 | -0.30 | 22-24 | 250 ℃ | 8.3 | |

| XG16S | 7.9-8.4 | -0.050 | 7.7-8.3 | ≥23 | -0.28 | 15-17 | 250 ℃ | 8.3 | |

| XG18S | 8.4-8.9 | -0.050 | 8.1-8.7 | ≥23 | -0.28 | 17-19 | 250 ℃ | 8.3 | |

| XG20S | 8.9-9.3 | -0.050 | 8.6-9.2 | ≥23 | -0.28 | 19-21 | 250 ℃ | 8.3 | |

| XG22S | 9.2-9.6 | -0.050 | 8.9-9.5 | ≥23 | -0.28 | 21-23 | 250 ℃ | 8.3 | |

| XG24S | 9.6-10.0 | -0.050 | 9.3-9.9 | ≥23 | -0.28 | 23-25 | 250 ℃ | 8.3 | |

| Sm2Co17 | XG24H | 9.5-10.2 | -0.025 | 8.7-9.6 | ≥25 | -0.20 | 22-24 | 350 ℃ | 8.3 |

| XG26H | 10.2-10.5 | -0.030 | 9.4-10.0 | ≥25 | -0.20 | 24-26 | 350 ℃ | 8.3 | |

| XG28H | 10.3-10.8 | -0.035 | 9.5-10.2 | ≥25 | -0.20 | 26-28 | 350 ℃ | 8.3 | |

| XG30H | 10.8-11.0 | -0.035 | 9.9-10.5 | ≥25 | -0.20 | 28-30 | 350 ℃ | 8.3 | |

| XG32H | 11.0-11.3 | -0.035 | 10.2-10.8 | ≥25 | -0.20 | 29-32 | 350 ℃ | 8.3 | |

| XG22 | 9.3-9.7 | -0.020 | 8.5-9.3 | ≥18 | -0.20 | 20-23 | 300 ℃ | 8.3 | |

| XG24 | 9.5-10.2 | -0.025 | 8.7-9.6 | ≥18 | -0.20 | 22-24 | 300 ℃ | 8.3 | |

| XG26 | 10.2-10.5 | -0.030 | 9.4-10.0 | ≥18 | -0.20 | 24-26 | 300 ℃ | 8.3 | |

| XG28 | 10.3-10.8 | -0.035 | 9.5-10.2 | ≥18 | -0.20 | 26-28 | 300 ℃ | 8.3 | |

| XG30 | 10.8-11.0 | -0.035 | 9.9-10.5 | ≥18 | -0.20 | 28-30 | 300 ℃ | 8.3 | |

| XG32 | 11.0-11.3 | -0.035 | 10.2-10.8 | ≥18 | -0.20 | 29-32 | 300 ℃ | 8.3 | |

| XG26M | 10.2-10.5 | -0.035 | 8.5-9.8 | 12-18 | -0.20 | 24-26 | 300 ℃ | 8.3 | |

| XG28M | 10.3-10.8 | -0.035 | 8.5-10.0 | 12-18 | -0.20 | 26-28 | 300 ℃ | 8.3 | |

| XG30M | 10.8-11.0 | -0.035 | 8.5-10.5 | 12-18 | -0.20 | 28-30 | 300 ℃ | 8.3 | |

| XG32M | 11.0-11.3 | -0.035 | 8.5-10.7 | 12-18 | -0.20 | 29-32 | 300 ℃ | 8.3 | |

| XG24L | 9.5-10.2 | -0.025 | 6.8-9.0 | 8-12 | -0.20 | 22-24 | 250 ℃ | 8.3 | |

| XG26L | 10.2-10.5 | -0.035 | 6.8-9.4 | 8-12 | -0.20 | 24-26 | 250 ℃ | 8.3 | |

| XG28L | 10.3-10.8 | -0.035 | 6.8-9.6 | 8-12 | -0.20 | 26-28 | 250 ℃ | 8.3 | |

| XG30L | 10.8-11.5 | -0.035 | 6.8-10.0 | 8-12 | -0.20 | 28-30 | 250 ℃ | 8.3 | |

| XG32L | 11.0-11.5 | -0.035 | 6.8-10.2 | 8-12 | -0.20 | 29-32 | 250 ℃ | 8.3 | |

| Hlokomela: · Re lula re tšoana le ka holimo ntle le haeba ho boletsoe ho tsoa ho moreki. Thempereichara ea curie le thempereichara ke tsa litšupiso feela, eseng joalo ka motheo oa ho etsa qeto.· Mocheso o phahameng ka ho fetesisa oa makenete oa fetoha ka lebaka la karo-karolelano ea bolelele le bophara le lintlha tsa tikoloho. | |||||||||

Molemo:

Tšebeliso ea limakete tsena e laoloa ke mocheso ka mefuta e mengata e fapaneng ho tloha ho 250ºC ho ea ho 350ºC mme mocheso oa tsona oa Curie o ka ba holimo haholo.

ho tloha ho 710 ho isa ho 880 °C. Ka hona, SmCo makenete e na le botsitso bo botle ka ho fetisisa ba makenete ka lebaka la khanyetso e phahameng ea mocheso o phahameng.

Limatla tsa SmCo li tšoauoa ka khanyetso e phahameng haholo ea kutu, ha ho na masela a hlokahalang bakeng sa ts'ireletso ea bokaholimo.

Sebopeho:

Bobebe ba limatlase tsa SmCo ke bofokoli bo tšoailoeng ba thepa - ntlha e lokelang ho tsotelloa haholo nakong ea ts'ebetso.

Limatla li entsoe ka galvanized kapa li koahetsoe ke cathodic electrodeposition bakeng sa lits'ebetso tse itseng.

Kopo:

Libakeng tsa mocheso o phahameng oa ts'ebetso, ho bola ho hoholo le ho hanyetsa oxidation ho bohlokoa. Joalo ka, Electronic magnetron,Magnetphetiso ea ic,

Phekolo ea Magnetic, Magnistor, joalo-joalo.

Litekanyetso tsohle tse boletsoeng li khethiloe ho sebelisoa lisampole tse tloaelehileng ho latela IEC 60404-5. Litlhaloso tse latelang li sebetsa e le litekanyetso tsa litšupiso mme li ka

fapana. The max. mocheso o sebetsang o ipapisitse le boholo ba makenete le ts'ebeliso e ikhethileng. Ho fumana lintlha tse ling ka kopo ikopanye le rona

baenjiniere ba lisebelisoa.